Shell Cordovan BeSpoke Shoes: When, Why, and How with Treccani Milano Posted on 21 Oct 11:01

Shell Cordovan leather is first created in the city of Cordoba, Spain, where the leather received its name. It was first prepared by the Moors in the area. And from this point in time it traveled to other cities over the centuries.

Shell Cordovan was adopted by The Horween Leather Company in 1905, the first of its' kind for razors. But when disposable razors began to appear there was less demand and they switched the process a bit to yield finer leather for the retail industry.

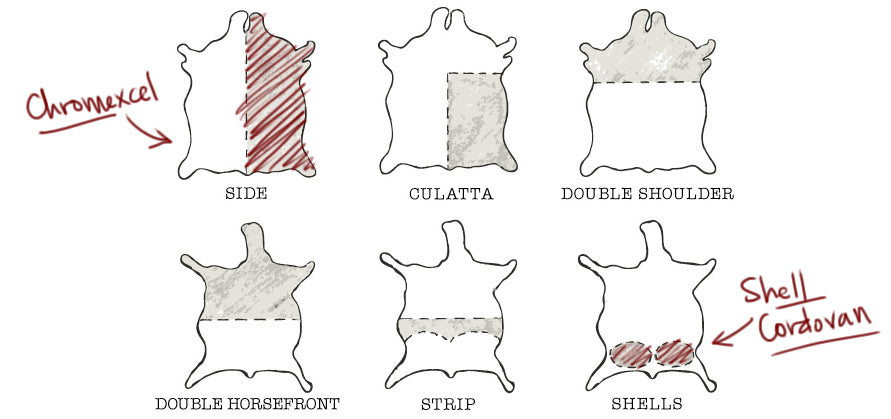

The term cordovan leather applies to the product of both the tanned fronts and tanned butts of a horse, but is especially used in connection with the term galoshes, meaning the vamps or boot-fronts of a shoe. Shell Cordovan comes from the fatty butt and shoulders of a horse. See image below.

Shell Cordovan, specifically from the Horween family factory, goes through a very intense process.

After removal from the horse, the hide is measured from the root of the tail 18 inches forward on the backbone. This decides the value of the hide based on length and quality. The hide is cut at right angles to the backbone and the resulting pieces termed a "front" (the forward part) and the "butt".

The Horween Leather Company in Chicago has the longest history of tanning Shell Cordovan of any tannery currently operating within the United States. As mentioned before in the early 1900's they switched from focusing on razors to shoes, gloves etc. And the process was fairly easy.

The raw material is imported horse hides that typically come from France and Canada where horses are still raised as part of food industry. The irregular oval shaped shells are tanned, stuffed, shaved, and then polished. The entire process takes approximately 6 months which is why it is so highly prized among leather enthusiasts. Let's break down the process . . .

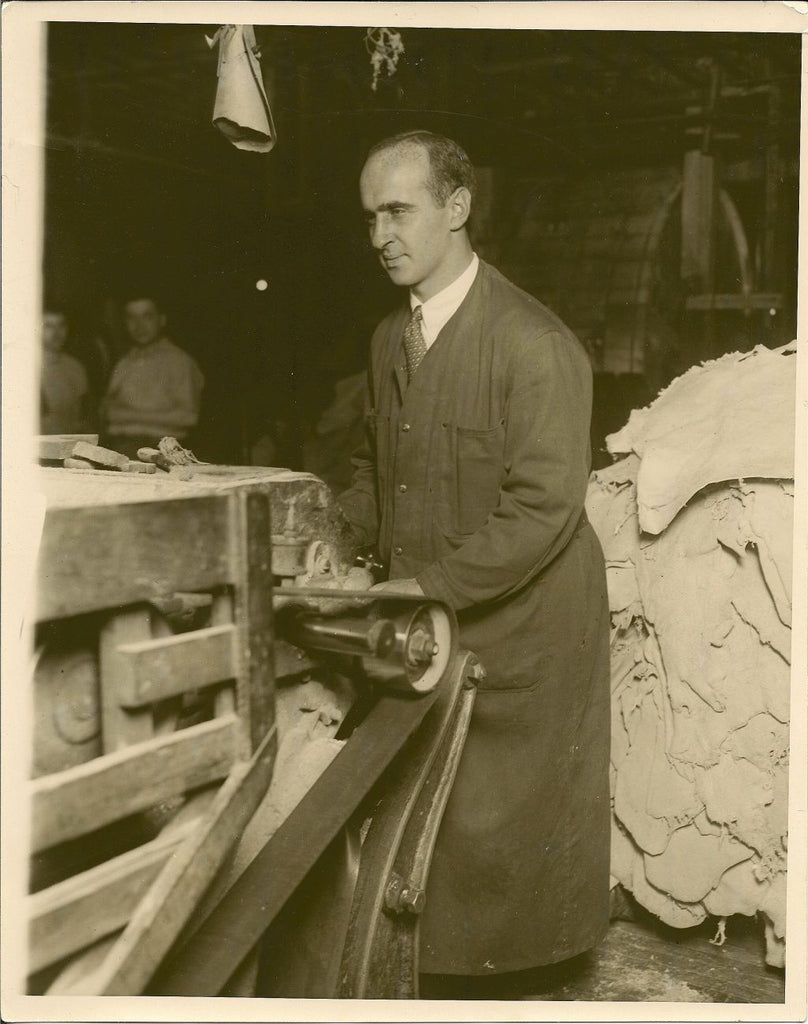

The most important step is called hot stuffing. After the razor craze ended Isidore Horween concocted a new mixture for tanning by increasing the fat and oil content to create more supple leather. All of this affected a process called hot stuffing. It is technically part of the tanning process where they reintroduce fats/greases/oils to nourish the fibers of the skin. These impart very favorable characteristics, like water resistance.

The process is started by steam-heating wooden drums, adding re-tanned or veg tanned leather, and add a special blend of greases, waxes, and oils that is privileged information and mixed in house special for each product. After this first initial process of adding oils and fats the hides are then pounded with greases, waxes, and oils into the skins by the tumbling action of the heated mills.

The process is specifically different from other fat liquor methods used where emulsified oils/fats are used to condition and nourish the fibers of the skin — the steam heat is not required to melt the oils/waxes/grease to penetrate the fibers. Hot stuffing is special because it allows them to use raw, less refined conditioning agents like beeswax, tallow, lanolin and paraffin.

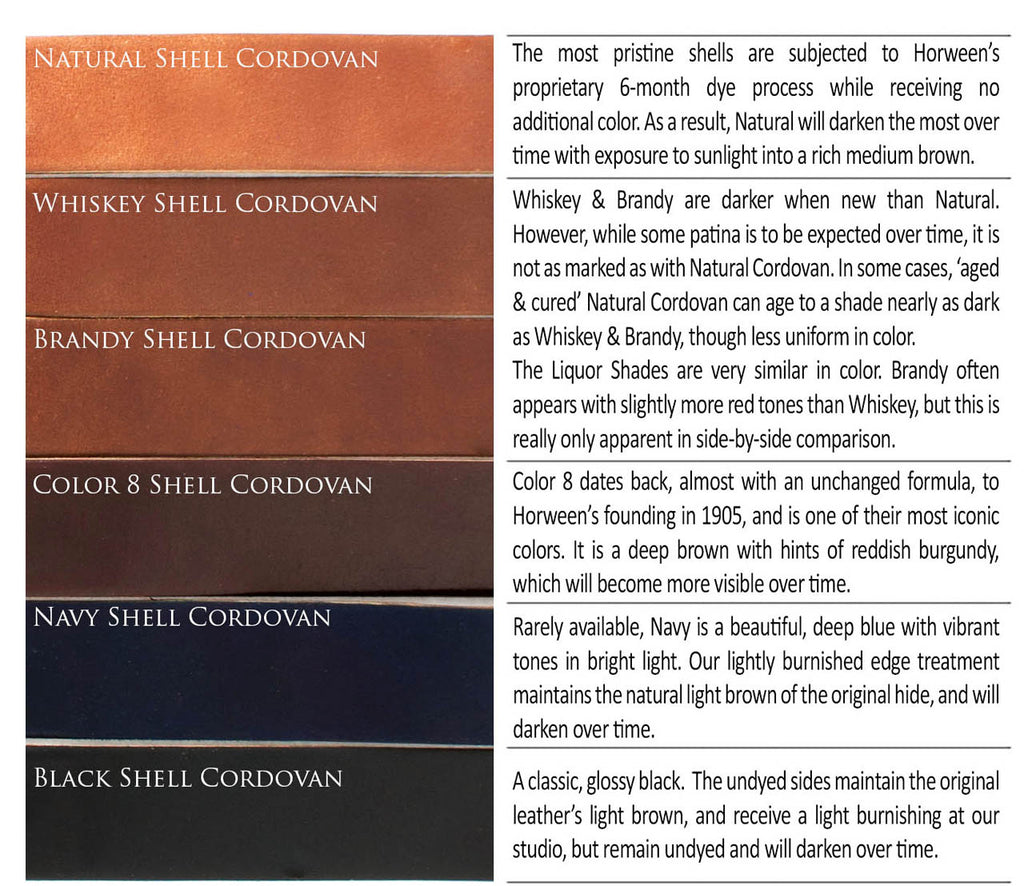

The re-tanning process after the first initial mixture is added to the leather that creates the sensory quality of the hides. Feel, look, smell etc. Due to the difficulty in applying dyes, Shell Cordovan is available in a narrow range of colors. Only those that you see in the diagram above are what Horween can offer.

Finally after it has been first initially hot stuffed the hides are then slicked onto glass frames to dry. Subsequently each shell is hand curried and shaved by highly skilled artisans to expose the shell. Dyes are hand rubbed on for a finish going deep into the hide. After all of that hands on work the shells are hand glazed to achieve the rich, glossy look and feel prized by fine craftsmen worldwide.

After being tanned, leather from the "front" is typically used in the production of gloves, or it can even be blackened, to be used in the tops of shoes. The "butt", after tanning, is passed through a splitting-machine which removes the grain, or hair side, revealing what is termed the "shell".

One such example of the finished product is our very own Venezia Shell Cordovan Derby Shoes pictured below.

Shell cordovan is always in short supply due to the limited horse hides available as well as the long production process.

A product made of shell cordovan will last multiple lifetimes. Because of the unique, non-creasing characteristics of shell cordovan, footwear can last a very long time by replacing the soles as needed. Thus in our own shop at Treccani Milano we can create shoes that can literally last you a lifetime.

References:

https://en.wikipaedia.org/wiki/Shell_cordovan

https://horween.com/leathers/shell-cordovan/

http://bestleather.org/all-about-shell0corodvan-with-horween-leather-co/

http://www.ashlandleather.com/Articles.asp?ID=251