The Rise of Italian Leather Tanneries: Treccani Milano's Tie to the Best Leather Products Posted on 22 Sep 16:27

Leather, from any country, has prehistoric origins as I am sure you can guess. Cave people as well as natives used leather for its durability, waterproof substances and natural warmth. As the human race evolved so did the way we viewed leather. Not only was leather created for warmth but also, much later, as fabulous fashionable accessories.

The creation of tanning leather first arose from a very common problem across nations. The leather would break down within a year, rot in the heat and stiffen in the cold and collapse over time from decomposition. The earliest techniques are thought to include smoking and rubbing of animal fats into the hide.

This problem was solved with early tanning methods which began in the Medieval time period. Thus medieval cities exploded with tanning methods unique to their region. Soon after this process grew in popularity, guilds-early style unions, formed to protect the secret tanning concoction of each tannery. These techniques are still closely protected family secrets that have been handed down from generation to generation. Most of which are in the areas that have been producing the world's best hides for over half a millennium.

But let’s now focus on Italy. Each region in Italy has their own specific style and leather product of choice. While not subject to these borders this is where most Italian leather comes from. For example; whole hides and bovine leather production for belts and soles is primarily located in Santa Croce, Florence; lamb skins are processed primarily in Solofra near Naples; and whole hides used for furniture or automotive upholstery are produced in Arzignano.

What leather do you have in your home? Chances are it is from one of those three places.

The most common form of tanning in Italy is called vegetable tanning. This is the earliest form of tanning dating back to 1500 B.C. originating in Egypt, Italy, and Greece. Italian tanneries are a combination of the past, present and future. While the ingredients stay the same technology has them striving boldly forward.

The tanning process uses eco-friendly natural tannins that occur in the bark of quebracho, chestnut or mimosa trees to give the leather its distinct personality and color.

Italy accounts for around 16% of world leather production and over two-thirds of all leather produced in Europe.

From Hide to Purse:

STEP 1: PICKING THE HIDE

The animal skins are immediately salted and cured for preservation during transport. When the hides arrive, master cutters separate them into three parts - sides, shoulders, and belly.

Here is a definition:

Croupon/Sides - Strongest and most valuable piece of the hide

Shoulder - Known for its neck rings

Belly - Due to the loose structure, it's not as firm

STEP 2: SOAKING AND LIMING

The skins are deaired, degreased, desalted, and soaked in water for two days. After soaking in the wooden drums, hides are taken out and treated with the milk of lime. Liming occurs when the weakening of hair is dependent on the breakdown of an amino acid called cystine. It's a removal process on the surface of the skin. Liming also removes grease and fat from the hide. Fleshing and Splitting is then carried out which removes all the hair once and for all.

The hides are then looked over by specialists in the tanning business to verify that all oils, hairs and other marks are removed from the hide. Once this verification is made the hides are placed in big drums to be soaked. This soaking removes the lime solution, lowers the pH level and smooths the grain for optimal conditions to be tanned.

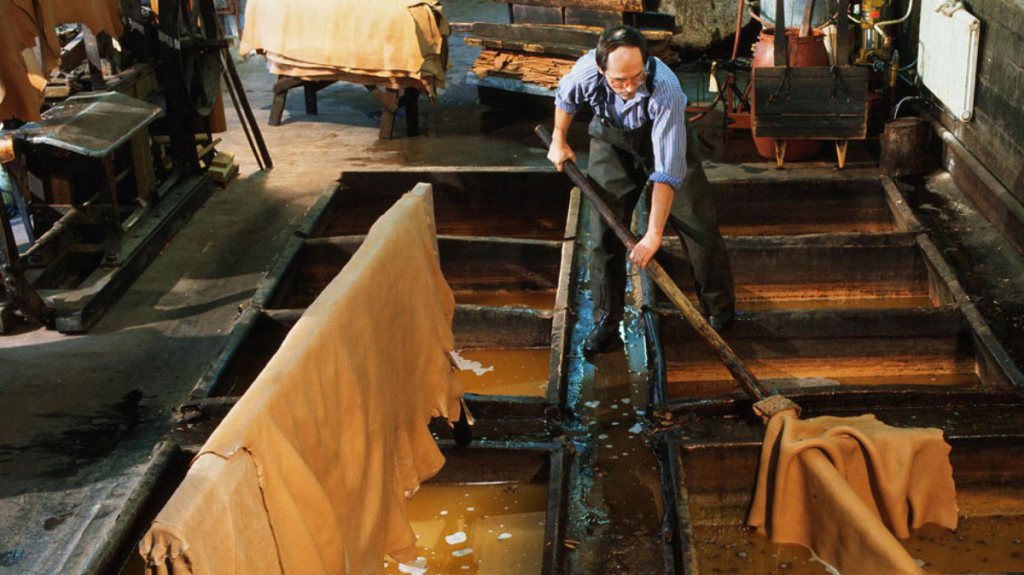

STEP 3: TANNING

The type of vegetable tanner you use yields a different result. We will discuss only the most popular. Chestnut wood is the most famous and ancient extract that is used in vegetable tanning because of its prevalence across France and Italy.

Leathers tanned with chestnut are elastic, light, and resistant to traction and abrasion. Chestnut tanned leathers are commonly used in the production of high-quality Italian shoes that are made with care and precision.

Another type of tanner is Quebracho extract that gives the leather a special reddish color with an unmistakable warm touch. Leathers produced using quebracho extracts are said to be enchanted with a sense of well-being that only gets better over time.

Once a tannin is selected the master must pick the right ratio of ingredients to have the desired result. Once that is done the leather is soaked again in large wooden drums for several days where hides are colored and softened. After being removed from the drums, we move on to drying, shaving, and finishing operations to remove the excess moisture and give the leather a uniform thickness.

STEP 4: DRYING & FINISHING

The leather, now tanned/coloured, is sent through a dry press where a majority of the water from tanning is removed.

That is the entire process. Spanning up to 40 days to bring you the Italian leather product of your dreams.

Sources images:

http://www.ind-svcs.com/blog/ammonium-sulfate-uses-leather-tanning-rinse-cellulose-insultaion-ph-control/

http://www.highsnobiety.com/2014/10/9/leather-jacket-buy/

http://www.ultrafabricsllc.com/Site/SubCollection/1/

http://www.fashionvortex.com/blog/a-trip-to-the-vegetable-leather-tanneries-in-italy-why-not/

References:

http://madeinitalyaccessories.com/history-of-leather

http://ballerleather.com/pages/history-of-italian-leather.html

http://www.wisegeek.com/what-is-so-special-about-italian-leather.htm

http://www.industryweek.com/companies-amp-executives/leather-production-still-fashionable-italy

http://ballerleather.com/pages/about/italian-leather-production.html